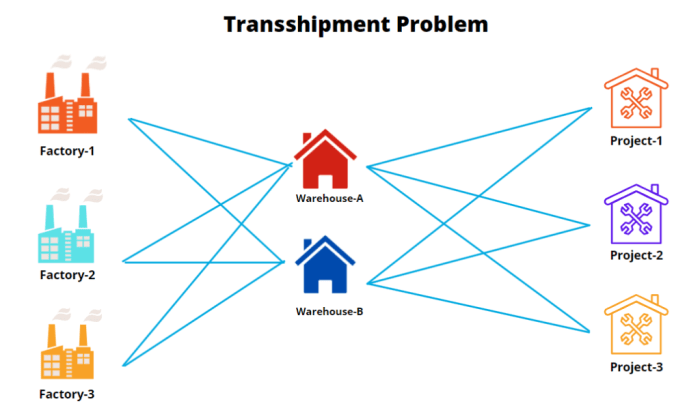

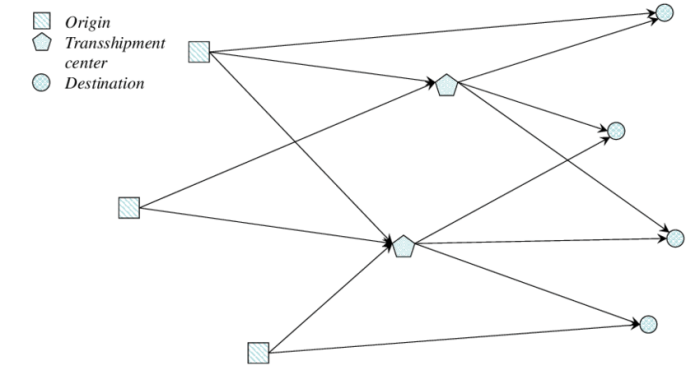

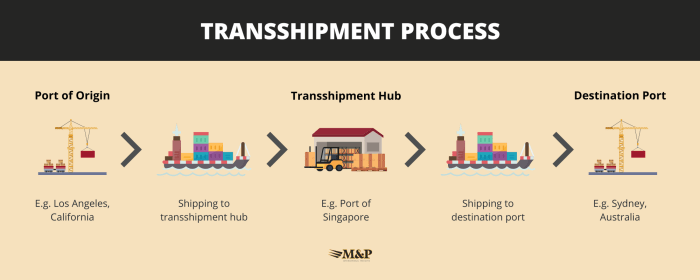

In a transshipment problem shipments – In a transshipment problem, shipments are moved from origin to destination through intermediate transshipment points. Understanding the types of shipments, costs, network design, and scheduling involved is crucial for efficient and cost-effective logistics operations.

Transshipment problems arise in various industries, including supply chain management, logistics, and transportation. By optimizing transshipment operations, businesses can improve efficiency, reduce costs, and enhance customer satisfaction.

Types of Shipments in Transshipment Problems: In A Transshipment Problem Shipments

In transshipment problems, shipments can be classified into three main types: origin shipments, destination shipments, and transshipment shipments. Each type of shipment plays a distinct role in the overall transshipment process.

Origin Shipments

Origin shipments are the shipments that originate from the initial source or production facility. These shipments are transported from their origin to a transshipment point, where they may be consolidated with other shipments or undergo other processing before continuing their journey to their final destination.

Destination Shipments

Destination shipments are the shipments that are delivered to the final recipient or consumer. These shipments are transported from the transshipment point to their final destination, where they are unloaded and delivered to the consignee.

Transshipment Shipments

Transshipment shipments are the shipments that are transported from one transshipment point to another. These shipments may be consolidated with other shipments or undergo other processing before continuing their journey to their final destination. Transshipment shipments are often used to optimize transportation costs and improve efficiency.

Transshipment Costs

Transshipment operations involve various cost components that directly impact their overall efficiency and profitability. Understanding these costs is crucial for optimizing transshipment processes and maximizing returns.

Transportation Costs

Transportation costs constitute a significant portion of transshipment expenses. These costs include the transportation of goods from the origin to the transshipment point, as well as from the transshipment point to the final destination. Factors influencing transportation costs include the distance, mode of transportation, and fuel prices.

Handling Costs

Handling costs encompass the expenses associated with the physical handling of goods during the transshipment process. These costs include loading and unloading goods, sorting and repackaging, and storage within the transshipment facility. Efficient handling practices can minimize these costs and improve the overall efficiency of the operation.

Storage Costs, In a transshipment problem shipments

Storage costs refer to the expenses incurred for storing goods at the transshipment facility. These costs are influenced by the duration of storage, the type of storage facility, and the handling equipment used. Optimizing storage space and implementing efficient inventory management systems can help reduce storage costs.

Transshipment Network Design

Transshipment network design involves the strategic planning and configuration of transshipment networks to optimize the movement of goods and minimize transportation costs. The design process considers various factors that influence the efficiency and cost-effectiveness of the network.

One crucial factor is the location of transshipment facilities. These facilities serve as intermediate hubs where shipments are consolidated, sorted, and redistributed. The optimal location of transshipment facilities depends on factors such as proximity to major transportation routes, availability of infrastructure, and the flow of shipments.

Capacity of Transportation Links

The capacity of transportation links, including roads, railways, and waterways, is another important consideration. The capacity of these links determines the maximum volume of shipments that can be transported through the network. When designing the network, it is essential to ensure that the capacity of transportation links is sufficient to handle the anticipated flow of shipments.

Flow of Shipments

The flow of shipments is a critical factor that influences the design of transshipment networks. The volume, origin, and destination of shipments determine the optimal configuration of the network. By understanding the flow of shipments, network designers can identify potential bottlenecks and design the network to minimize delays and maximize efficiency.

Optimization Techniques

Various optimization techniques are employed to design efficient and cost-effective transshipment networks. These techniques include:

- Linear programming: A mathematical technique used to optimize the flow of shipments and minimize transportation costs.

- Network flow algorithms: Algorithms that find the maximum flow or minimum cost flow through a network.

- Simulation modeling: A technique that simulates the operation of a transshipment network to evaluate different design alternatives.

Transshipment Scheduling

Scheduling plays a critical role in ensuring the smooth and efficient operation of transshipment facilities. Coordinating the movement of shipments through these facilities involves a complex interplay of factors, including the availability of transportation resources, the capacity of transshipment hubs, and the time constraints imposed by customer demand.

Scheduling Methods

Various scheduling methods are employed in transshipment problems, each with its advantages and disadvantages. These methods include:

First-Come-First-Served (FCFS)

Shipments are processed in the order they arrive at the transshipment facility. This method is simple to implement but can lead to inefficiencies if shipments with urgent deadlines are delayed by slower-moving shipments.

Shortest Processing Time (SPT)

Shipments with the shortest processing times are given priority. This method helps reduce the average waiting time for shipments but can result in larger shipments being delayed.

Earliest Due Date (EDD)

Shipments with the earliest due dates are given priority. This method ensures that urgent shipments are processed promptly but can lead to longer waiting times for non-urgent shipments.

Critical Ratio (CR)

The critical ratio is calculated by dividing the remaining processing time by the remaining time until the shipment’s due date. Shipments with the highest critical ratios are given priority. This method balances the urgency of shipments with their processing times.

Real-World Applications of Transshipment Problems

Transshipment problems are widely applicable in various industries, offering efficient solutions for complex logistics and transportation challenges. From supply chain management to logistics and transportation, transshipment models have demonstrated significant benefits in optimizing resource allocation, reducing costs, and enhancing overall operational efficiency.

Implementing transshipment solutions, however, presents its own set of challenges. These include managing large-scale data sets, accounting for real-time constraints, and addressing the complexities of coordinating multiple stakeholders involved in the transshipment process.

Case Study: Supply Chain Management

In supply chain management, transshipment models have been successfully employed to optimize the distribution of goods from multiple suppliers to multiple customers. By determining the optimal transshipment points and routes, businesses can minimize transportation costs, reduce inventory levels, and improve customer service.

For instance, a large retail chain implemented a transshipment model to manage its distribution network. The model helped the company identify the most cost-effective transshipment points, resulting in a 15% reduction in transportation costs and a 10% improvement in customer service levels.

Case Study: Logistics

In the logistics industry, transshipment models have been used to optimize the movement of goods through complex transportation networks. By considering factors such as vehicle capacity, travel time, and transshipment costs, logistics companies can develop efficient and cost-effective transportation plans.

For example, a global logistics provider used a transshipment model to optimize its transportation network for a major automotive manufacturer. The model helped the company reduce transportation costs by 8% and improve delivery times by 5%.

Expert Answers

What are the different types of shipments in transshipment problems?

Origin shipments are those that originate at the starting point of the journey. Destination shipments are those that end at the final destination. Transshipment shipments are those that are moved from one mode of transportation to another or from one location to another during the journey.

What are the key cost components associated with transshipments?

Transportation costs include the costs of moving shipments from one location to another. Handling costs include the costs of loading, unloading, and storing shipments. Storage costs include the costs of holding shipments in warehouses or other storage facilities.

What factors influence the design of transshipment networks?

The location of transshipment facilities, the capacity of transportation links, and the flow of shipments all influence the design of transshipment networks.